UK-INDIA CRITICAL MINERALS PARTNERSHIP GAINS MOMENTUM WITH GROUNDBREAKING COLLABORATION

By Marie Carter-Robb • Posted in Engineering

The Centre for Process Innovation (CPI), based in Sedgefield, County Durham, and the Institute for Manufacturing (IfM) at the University of Cambridge are collaborating with international partners in a pioneering UK-India initiative aimed at enhancing innovation and investment across the entire life cycle of critical minerals. This partnership includes establishing a dedicated observatory to track supply chains and material flows for critical minerals from their extraction to their use in electric vehicles.

The collaboration was announced after the UK Foreign Secretary, Rt Hon David Lammy, visited India to underscore the strengthening relationship between the two nations through the launch of the UK-India Technology Security Initiative.

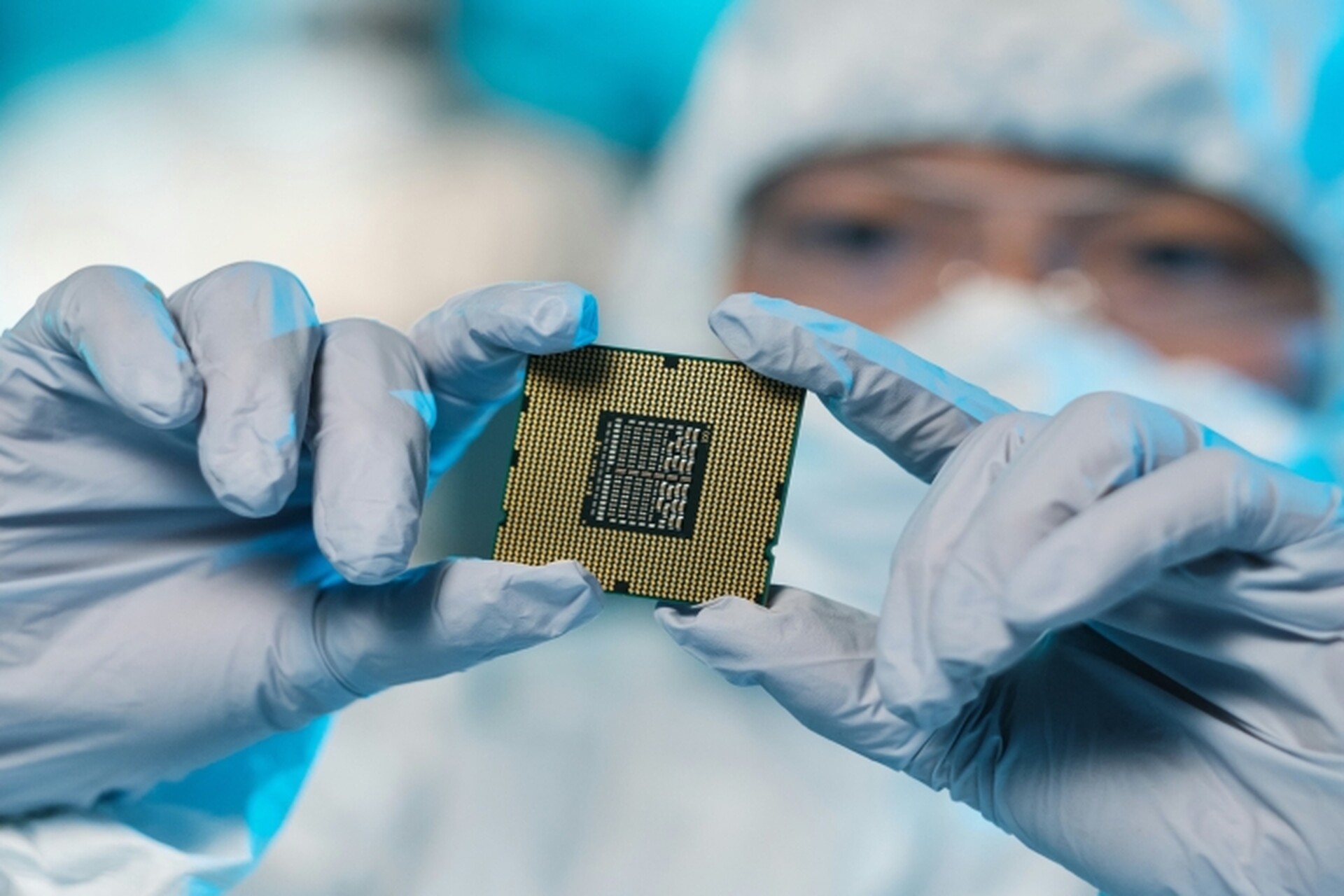

Building upon the ambitious vision set out in the India-UK Roadmap 2030, this initiative will deepen collaboration in critical and emerging technologies, prioritising sectors such as advanced materials, semiconductors, and critical minerals. It will also support existing partnerships, expand mandates, and establish new frameworks for cooperation.

Critical minerals—including lithium, copper, nickel, and cobalt—are indispensable to modern technology and the global economy, especially in high-tech industries and clean energy sectors. Recognising the urgency of responsible mining, refining, and recycling of these materials, the UK and India are committed to securing the critical mineral supply chains essential for a transition to net zero.

In partnership with the Indian Institute of Technology (IIT) Bombay, IfM will lead the establishment of an observatory to foster collaboration among academics, innovators, and industry stakeholders by sharing supply chain data.

This observatory will create an industrial data infrastructure for both the UK and India, enabling the identification of risks, recycling opportunities, and resource shortages. The initiative will also test advanced technologies, such as personalised AI, to stabilise supply chains and strengthen trade links between the two countries. Through this platform, knowledge sharing around extraction and refining will be expanded to enhance critical mineral capabilities.

CPI’s role in the initiative includes addressing industrial challenges by launching an Innovation Sprint programme, designed to explore sustainable manufacturing techniques for critical mineral extraction and purification.

Professor Tim Minshall, Head of IfM, highlighted the significance of this collaboration: “Given the global challenges related to critical minerals affecting all nations, this programme is extremely important and timely. This observatory will play a key role in ensuring that technological innovation can be achieved in a way that is resilient, secure and sustainable. We are delighted that this programme is being taken forward as an international partnership, reflecting the fact that addressing critical mineral challenges requires an international approach.”

Dr Arun Harish, Chief Strategy Officer at CPI, added: “Partnerships such as these are going to provide the blueprint for how we solve some of the biggest industrial challenges. By working closely with colleagues in India, we can find opportunities that benefit both nations’ energy security and crucially provide some much-needed answers on how we can move sustainably away from fossil fuels. This work will encourage investment in key sectors and eventually help provide economic opportunity for people in the UK and India as we work together to develop the industries of the future.”

Dr Mukesh Kumar, Head of IfM’s Industrial Resilience Group, commented on IfM’s role: “The University of Cambridge's IfM Industrial Resilience Group is leading part of this project, which is establishing one of the world’s first critical mineral supply chain observatory labs. By building the largest data infrastructure for critical minerals, we aim to identify supply chain vulnerabilities, enhance capabilities, and promote ESG and sustainability.”

Professor Ramaswamy Murugavel of IIT Bombay emphasised the collaborative potential of this initiative: “At IIT Bombay, we are excited to collaborate on the UK-India Critical Mineral Supply Chain Observatory, a project that addresses a key area of global importance. Leveraging our expertise in materials chemistry, we will focus on assessing and advancing extraction, refining, and recycling technologies for critical minerals. This collaboration not only fosters innovation but also strengthens the technological and scientific ties between India and the UK.”

Mrutyunjay Suar, Chairman of the Bhubaneswar City Knowledge Innovation Cluster (BCKIC), commented: “The UK-India partnership marks a noteworthy milestone in driving the innovation and sustainability for critical minerals. Both countries aligning their strengths will not only address immediate challenges but also set the platform for long-term collaboration. CPI plays a vital role by leading one of these initiatives and catalysing the synergy between industry leaders, academia, and research institutes, which is crucial in developing tangible technologies that can add immense value to the critical mineral sector. We, at BCKIC, are committed to fostering these connections and building the capacity of Indian miners.”

Professor Paul Anderson, Co-director of the Birmingham Centre for Strategic Elements and Critical Materials (BCSECM), added: “Key technologies that underpin the transition to ‘Net Zero’ such as wind turbines, lithium-ion batteries and hydrogen fuel cells are dependent on secure access to critical materials, but the required mineral resources, processing capability and expertise in recycling to ensure this are rarely found in one region alone. This landmark UK-India collaboration will promote improved elemental stewardship in both countries and help secure access to the critical materials that will make net zero a reality.”

This initiative is a key development in aligning the UK and India’s strengths for sustainable industry and underscores the importance of international cooperation in achieving resilient, secure, and sustainable critical mineral supply chains.