Sector News > Civil Engineering

DRAINAGE TEAMS DESCEND INTO WELSH MOUNTAIN TO KEEP EUROPE’S LARGEST CAVERN POWER STATION FLOWING

By Marie Carter-Robb • Posted in Civil Engineering

In a remarkable engineering feat deep within the Welsh mountains, national drainage contractor Lanes Group plc has successfully tackled a complex challenge at Dinorwig hydroelectric power station, the largest facility of its kind in Europe.

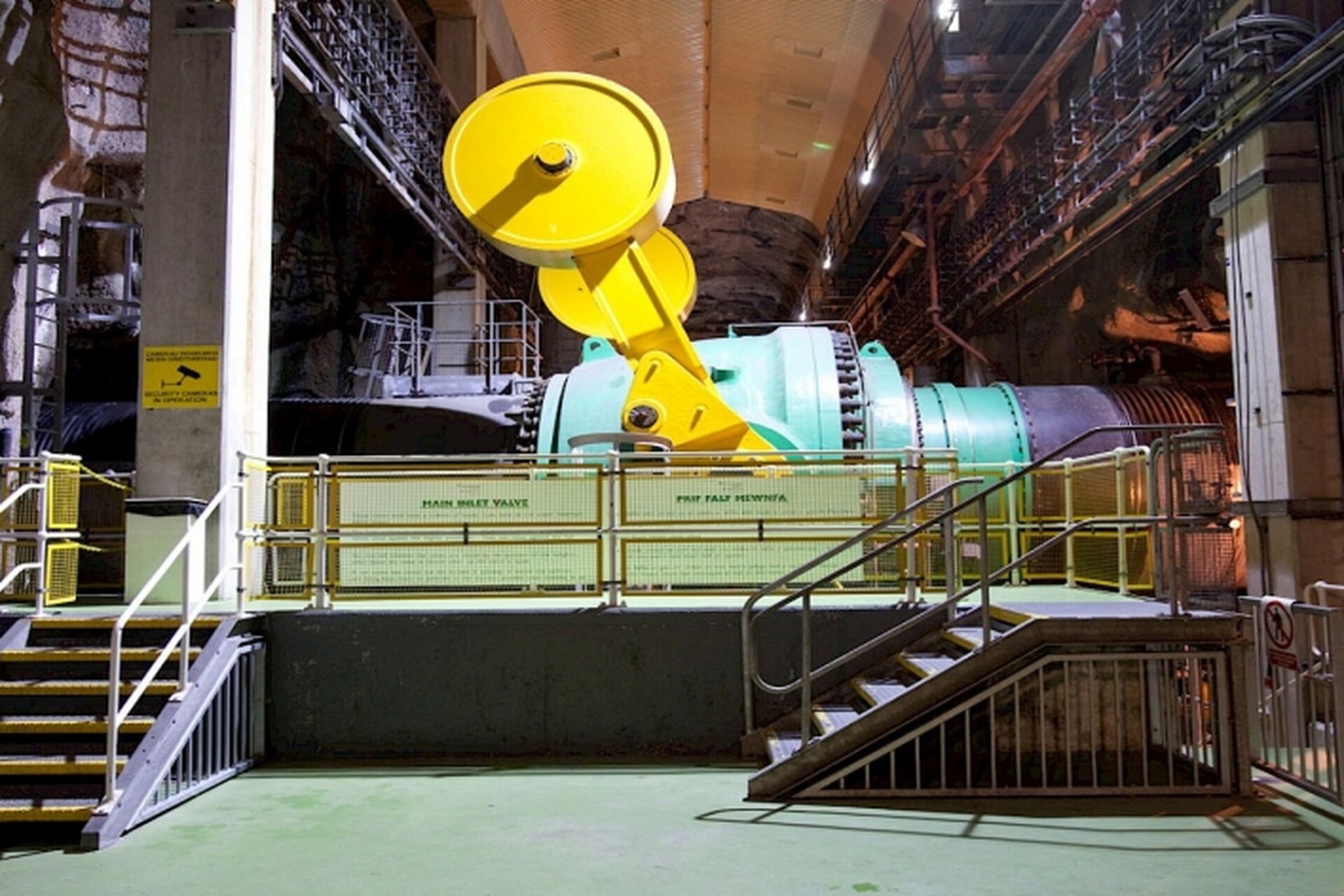

Located within Mt Elidir Fawr, this iconic power station is set within Europe's largest man-made cavern, a testament to human ingenuity and engineering prowess.

Lanes Group, a company with roots in the North West and operational headquarters in Eccles, Greater Manchester, was called upon by First Hydro Company to address a critical issue affecting the station’s drainage system. The power station, which houses six 300 megawatt generators capable of reaching full power in just 16 seconds, relies on an efficient drainage system to function optimally. Over time, calcite and silt deposits had built up in the drainage pipes within the main inlet valve gallery, posing a significant risk to the station’s operations.

Amy Pritchett, Engineering Geologist for First Hydro, emphasised the importance of the task: “The calcite deposits, in particular, were beginning to compromise the gallery's drainage system, so the work Lanes has done for us has been very important. Conventional methods of clearing the pipes, such as pressure washing and rodding, didn’t work, so we needed the specialist equipment and skills Lanes has to provide an effective solution.”

The drainage team from Lanes Chester, supported by their Sewer Renovation Division, undertook the challenging task using a combination of high-tech tools. Among these was the Picote Maxi Miller robotic grinder, which, along with high-pressure jetting, was instrumental in removing deposits from the enclosed pipes. The precision of the operation was ensured by a mini camera integrated into the cutting head, allowing real-time monitoring.

For the most stubborn deposits, Lanes employed an IMS robotic cutter, again monitored through HD-quality CCTV to ensure thorough and efficient progress. All debris was swiftly removed using the jet vac tanker's powerful vacuumation system, preventing any risk of further blockages downstream.

The open channels within the gallery were cleared mechanically and through pressure washing, with the resulting debris similarly vacuumed up to leave the area clear. This meticulous approach ensured that the seepage water could once again flow freely into the large sump, restoring the drainage system's full capacity.

Sian Wyn Jones, Lanes Chester Area Development Manager, expressed pride in the project: “This project demonstrated the range of capabilities Lanes can bring to bear to resolve tough drainage challenges. The expertise, specialist equipment, and determination our teams bring to the job underpin the success of a tricky task. It was also a privilege for our teams to support such an awesome strategic asset that’s unique in its scale and purpose in the UK.”

The Dinorwig Power Station, a marvel of civil engineering built within a disused slate mine in the heart of Snowdonia, has been operational since 1984. It remains a vital part of the UK’s energy infrastructure, capable of delivering electricity to meet sudden spikes in demand. The station, often referred to as ‘the concert hall’ due to the immense size of its turbine hall, was the largest civil engineering project ever commissioned by the UK government when it began in 1974.

Lanes Group’s involvement in maintaining this crucial facility highlights not only their technical expertise but also their integral role in supporting the UK’s energy infrastructure. With its roots firmly planted in the North West, Lanes continues to be a key player in ensuring that critical services like those at Dinorwig remain operational, even when faced with the toughest of challenges.